Are you on an Industrial Digital Transformation journey?

Industrial DX promises to unlock value in your operational data, but the transformation can be daunting. By simplifying how you connect your OT data with the cloud, we can help you gain a competitive edge.

Allied Telesis Industrial-Grade solutions are

Reliable

Hardened products with fault-tolerant technologies ensure your operatons run non-stop.

Secure

Advanced automated security features protect against intrusion attempts and data breaches.

Flexible

Powerful automation tools and standards-based interoperability simplify integration and increase agility.

Easy to Use

Complete network visibility and an intuitive dashboard mean less down time and easier management.

Smart factories and manufacturing networks undergoing digital transformation (DX) are upgrading existing sites to improve operational excellence and flexibility by adapting production processes to take on more orders, meet shifting market requirements or support newer and more complex products.

Data drives Operational Excellence in Digital Industry.

Acting on Data

Automate and optimize production processes (e.g., cobots for packaging lines).

Collecting Data

Gather real-time data from IIoT sensors, devices, and PLCs.

Analyzing Data

Cloud-based analytics use AI to unlock insights from production data for improved operational and business decision-making.

Acting on Data

Automate and optimize production processes (e.g., cobots for packaging lines).

Collecting Data

Gather real-time data from IIoT sensors, devices, and PLCs.

Analyzing Data

Cloud-based analytics use AI to unlock insights from production data for improved operational and business decision-making.

Reliable delivery of real-time data is critical.

Is your network up to the job?

Flexible

Built with standards-based technologies and industrial protocols to interoperate freely, our switches fit into your existing IACS networks. Our powerful automation tools enable rapid commissioning and network changes to increase business agility. Support for open-standards offer easy integration and total flexibility.

Flexible

Built with standards-based technologies and industrial protocols to interoperate freely, our switches fit into your existing IACS networks. Our powerful automation tools enable rapid commissioning and network changes to increase business agility. Support for open-standards offer easy integration and total flexibility.

Reliable

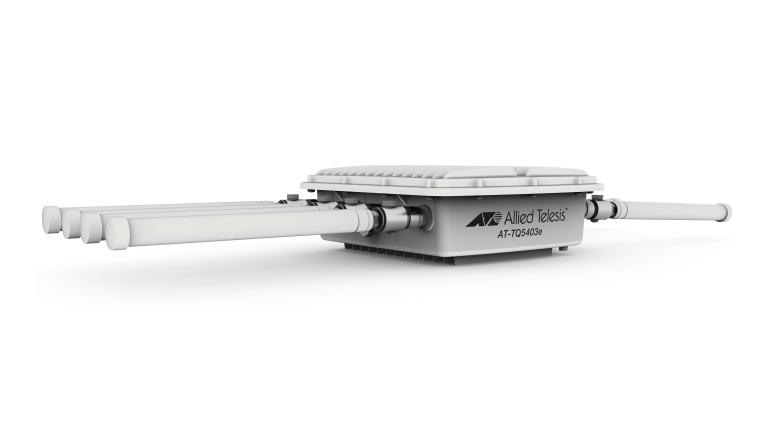

Rugged hardware designed for severe environments with electromagnetic noise, wide temperature, humidity, vibration, and proximity to fire. Hardened Wi-Fi APs provide optimal coverage and a seamless mobile experience anywhere you need it. Resilient network technologies maintain non-stop connectivity even if failures occur.

Reliable

Rugged hardware designed to withstand severe environments with electromagnetic noise, wide temperature, humidity, vibration, and proximity to fire. Hardened Wi-Fi APs can be located for best coverage and seamless mobile experience. Resilient network technologies maintain non-stop connecttivity even if failures occur.

Secure

Advanced automated cybersecurity features and SDN-based micro-segmentation ensure robust protection for both IT and OT networks to prevent data breaches and hamper intrusion attempts by limiting lateral spread of threats.

Secure

Advanced automated cybersecurity features and SDN-based micro-segmentation ensure robust protection for both IT and OT networks to prevent data breaches and hamper intrusion attempts by limiting lateral spread of threats.

Easy to Use

Intuitive network dashboards and powerful automation tools simplify daily network management and reduce the risk of human errors. One management platform to manage both IT and OT wired & wireless networks reduces the burden on your IT/OT engineers.

Easy to Use

Intuitive network dashboard and powerful automation tools simplify daily network management and reduce risk of human errors. One management platorm to manage both IT and OT wired & wireless networks reduces the burden on your IT/OT engineers.

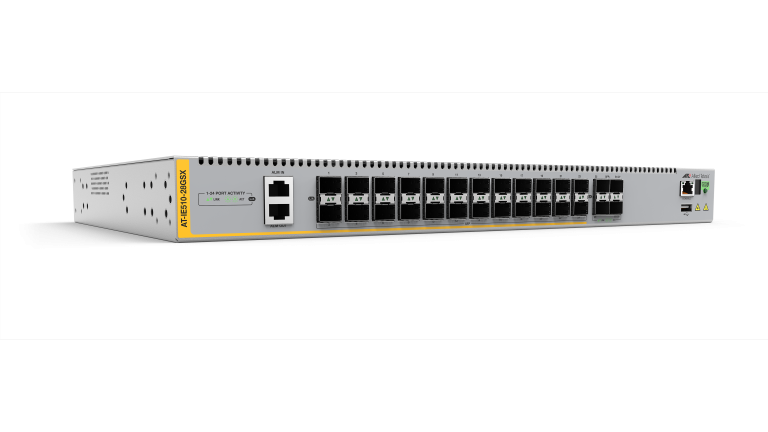

Allied Telesis IE-series switches offer unbeatable reliability, flexibility, and ease-of-use with their combination of OpenFlow for SDN-based applications and network automation tools shared with our enterprise networking products for simplified IT/OT network management.

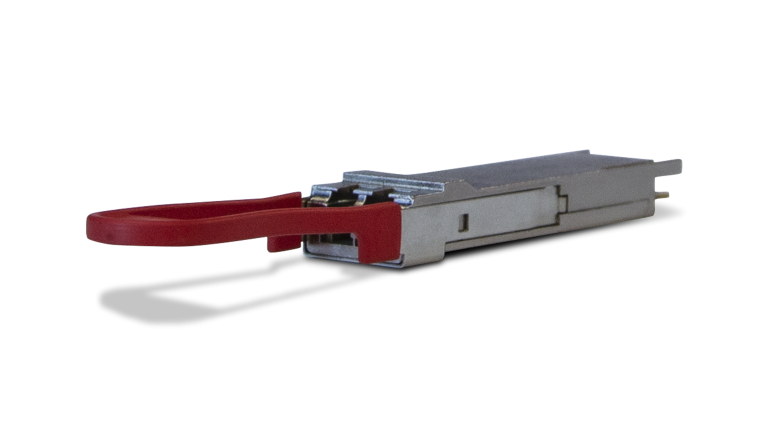

Our switches are complemented by a range of extended temperature connectivity products and wireless access points to provide a complete access solution for harsh environments.

Our Industrial-Grade solutions offer an unbeatable combination of reliability and security with flexibility and ease-of-use. Call us today to find out how they can ease your Industrial DX journey.

Ready to take the next step?

Chat with our sales team today about how our award-winning products and services can strengthen your business.